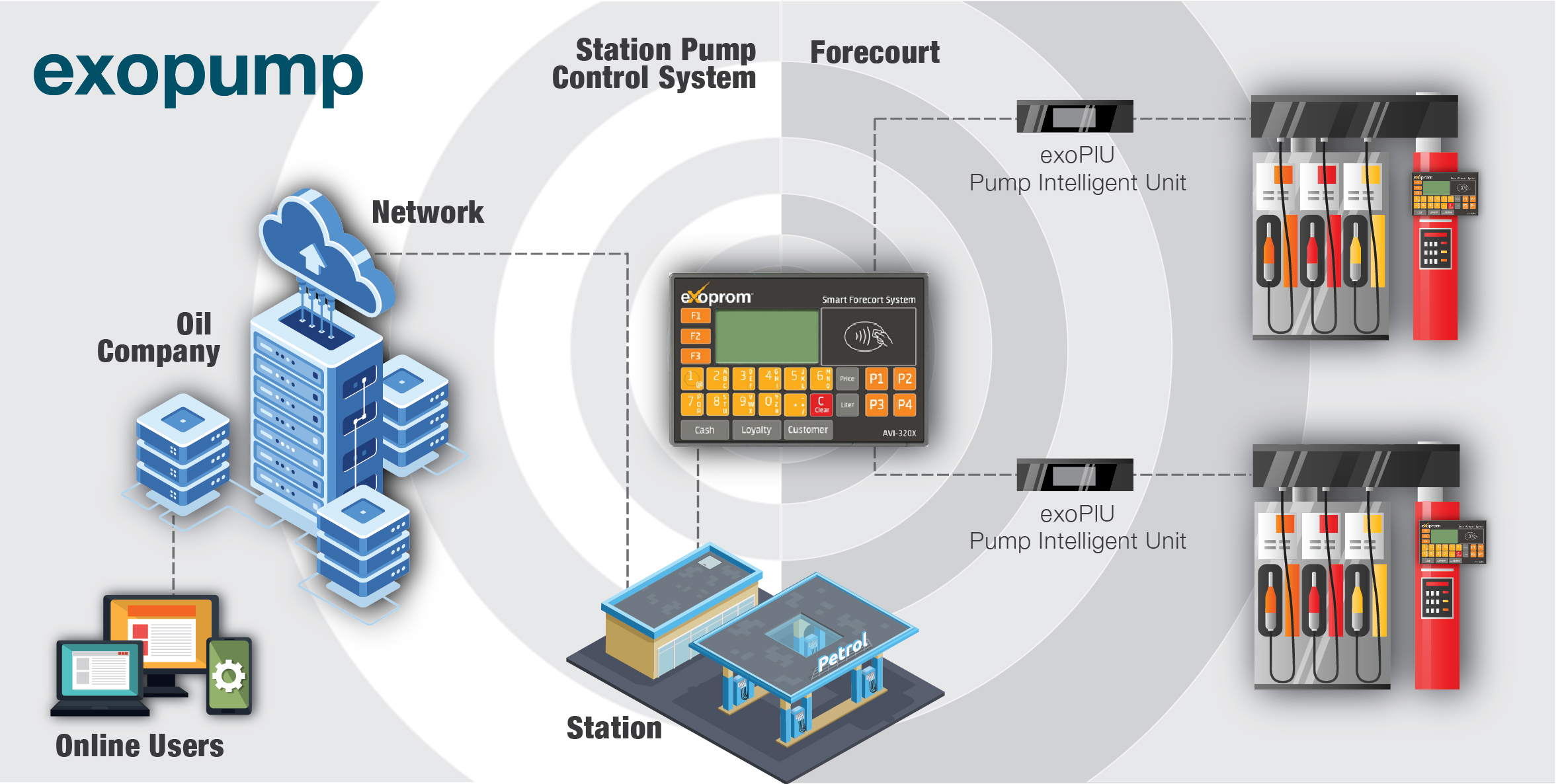

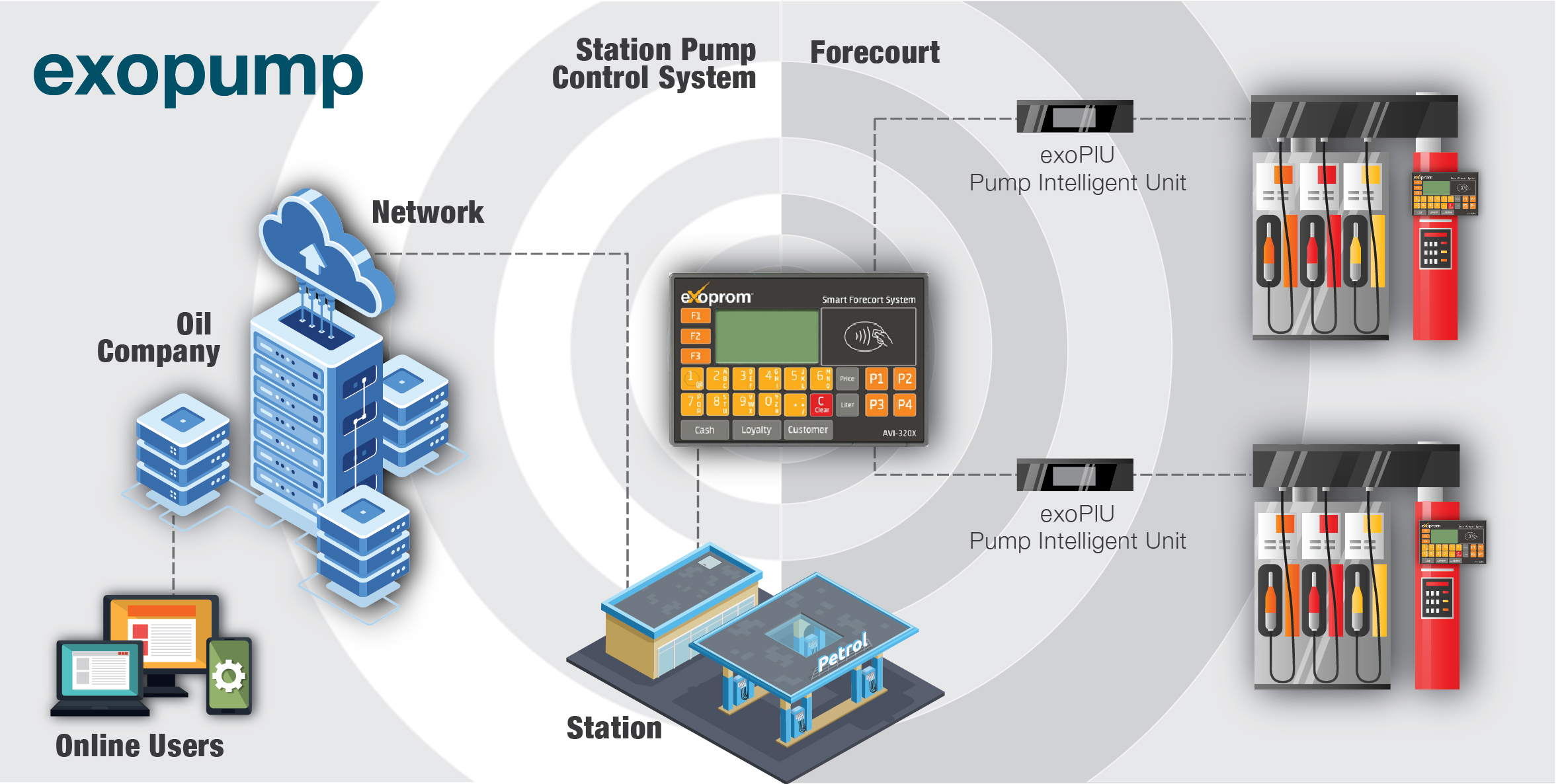

Exopump - Keep An Eye On Your Fuel Pumps

Exopump is an automatic fuel supply control and monitoring system for your fuel dispensers at the field. It powers the secure, online and offline simple refueling for stations with clear and measurable value to both oil companies and commercial fleets.

Exopump is a computerized solution for automatic controlling and monitoring of all fuel dispensers from your head office. It is a full-featured, web or desktop based system for administering, measuring data and getting reports for your pumps. It consists of a web and desktop application and various communications options and data collection applications.

General Parameters

Fuel Filling Information is Reported in the Details Below

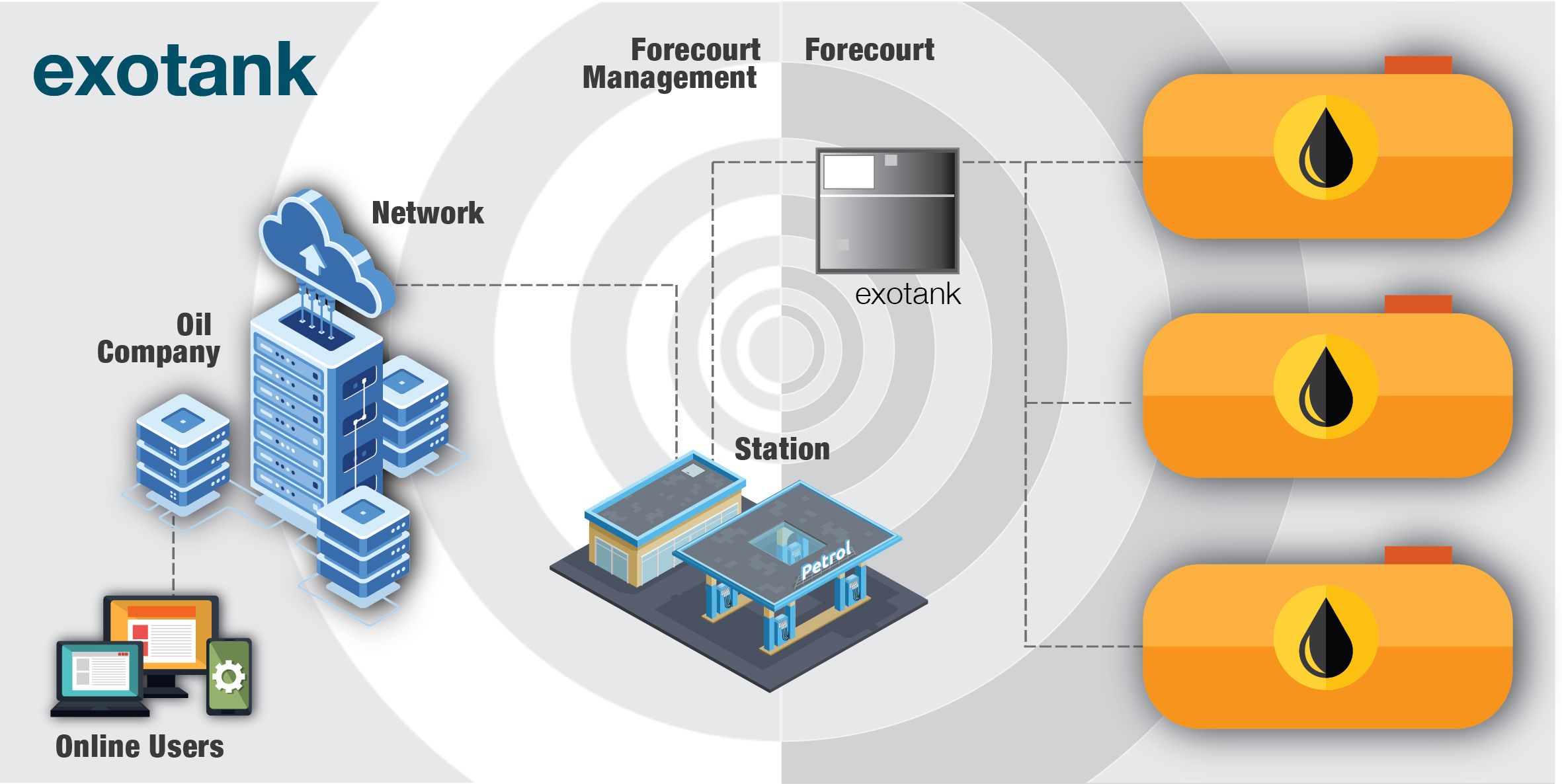

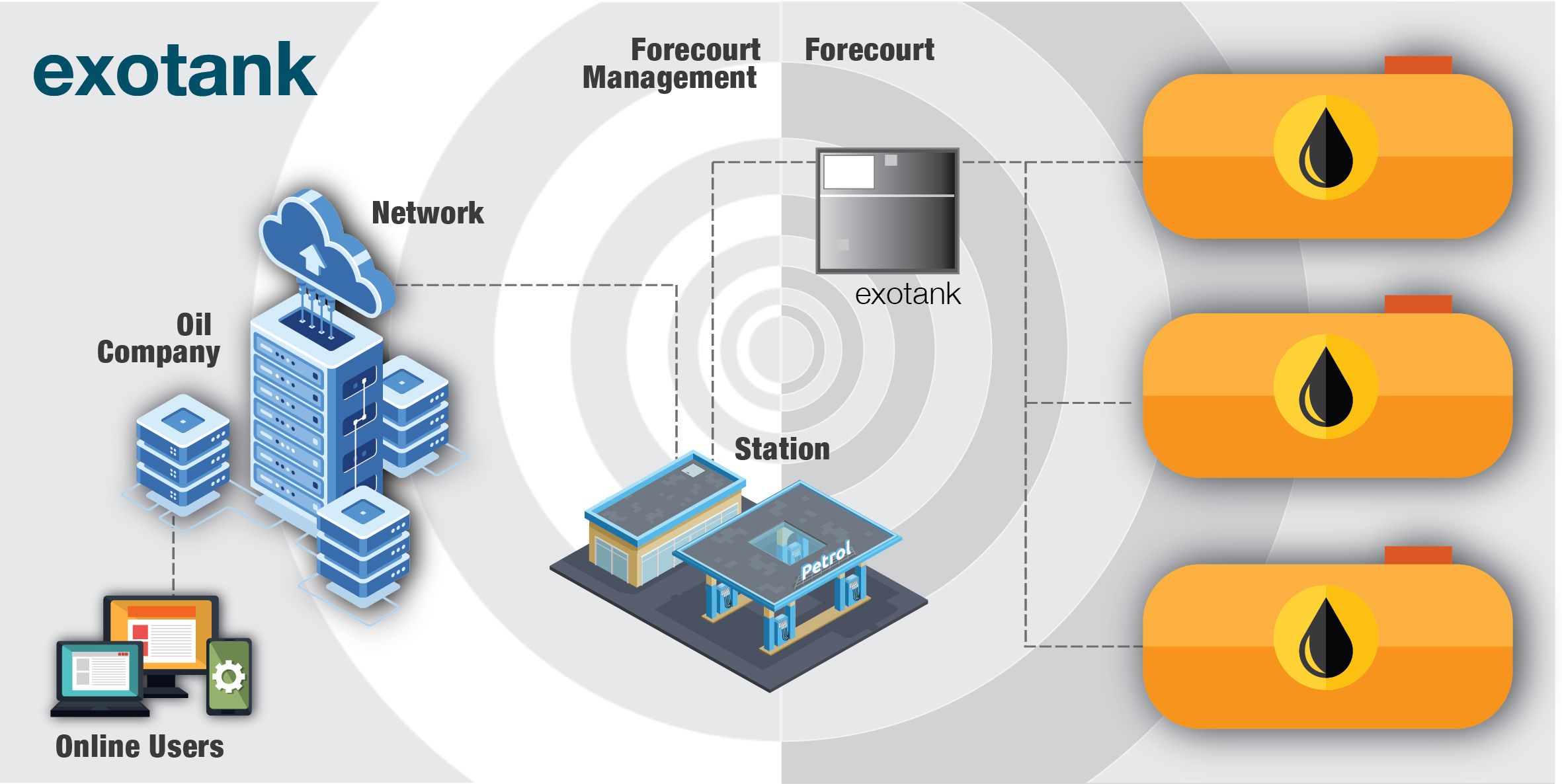

Exotank - Control Your Fuel, Adblue Storage Tanks With Wet Stock Management

Exotank - Control Your Fuel, Adblue Storage Tanks With Wet Stock Management

Exotank is a state of the art automated liquid inventory system designed to monitor, control and analysis real time liquid levels at storage tanks to reduce fuel loses, improve station network efficiency and gross margin. Exotank could be applied both as cabled or completely wireless depending on clients’ needs.

Fuel or adblue management begins with proper control of fuel inventory and smart purchasing policy and procedures. Exotank integrates with fuel station equipment and collects bulk data from all areas, tanks and pumps. Thanks to its smart algorithms, Exotank easily detects irregularities in station operations and stock levels at the beginning. It analyzes possible causes and allows you to make important decisions necessary to improve station performance. Exotank also tracks fuel stock history and looks for consistency in fuel input and output.

Exotank helps you consolidate the fuel you have on hand and record the correct amount of fuel per location by fuel type, allowing you to eliminate costly emergency deliveries. The Exotank is powered by Exosite software and fuel delivery is controlled and recorded in real time.

Exotank allows you to view full product usage and consolidate between products received, products shipped, and products left in storage tanks. All this will be done automatically via magnetostrictive independent level indicator sensors mounted on each storage tank.

General Parameters

Exotank enable to see full product use and consolidate between products received, products dispatched and products left in the storage tanks. All this will be done automatically via magnetostrictive standalone level gauge sensors mounted on each storage.

Delivery and Temperature Monitoring

Because Exotank continuously monitors inventory levels and temperature we are able to verify delivery amounts for short deliveries and identify offset fill leaks and hot product related losses issues.

Real Time Theft Alert

The real time nature of CFM means thefts can be identified quickly and accurately. The system will send out SMS or email alerts within couple of minutes of a theft occurring.

Meter Drift Analysis

Dispensers giving away fuel due to meter drift are probably the single biggest component of fuel loss. This service quickly highlights individual nozzles that can be economically cut back to strike without carrying out disruptive meter proving checks across the whole site.

Flow Rate Analysis and Dispenser Utilisation

The service also monitors the flow patterns of each dispenser throughout the transaction to identify any maintenance or performance issues. For example, slow flow due to blocked filters or significant changes in nozzle usage.

Water in Tanks

The presence of water in tanks can be advance warning of quality issues such as biological contamination and phase separation.

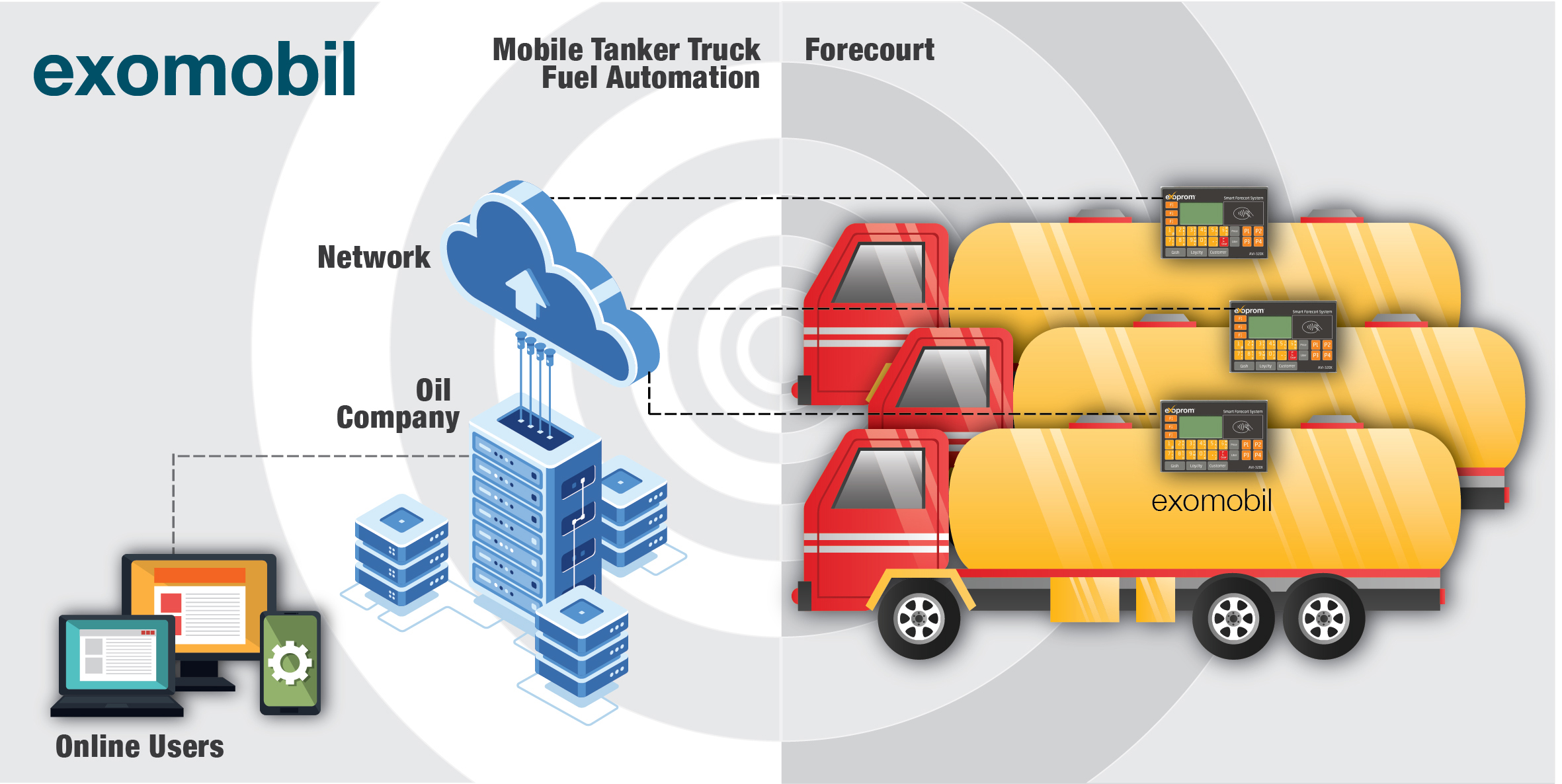

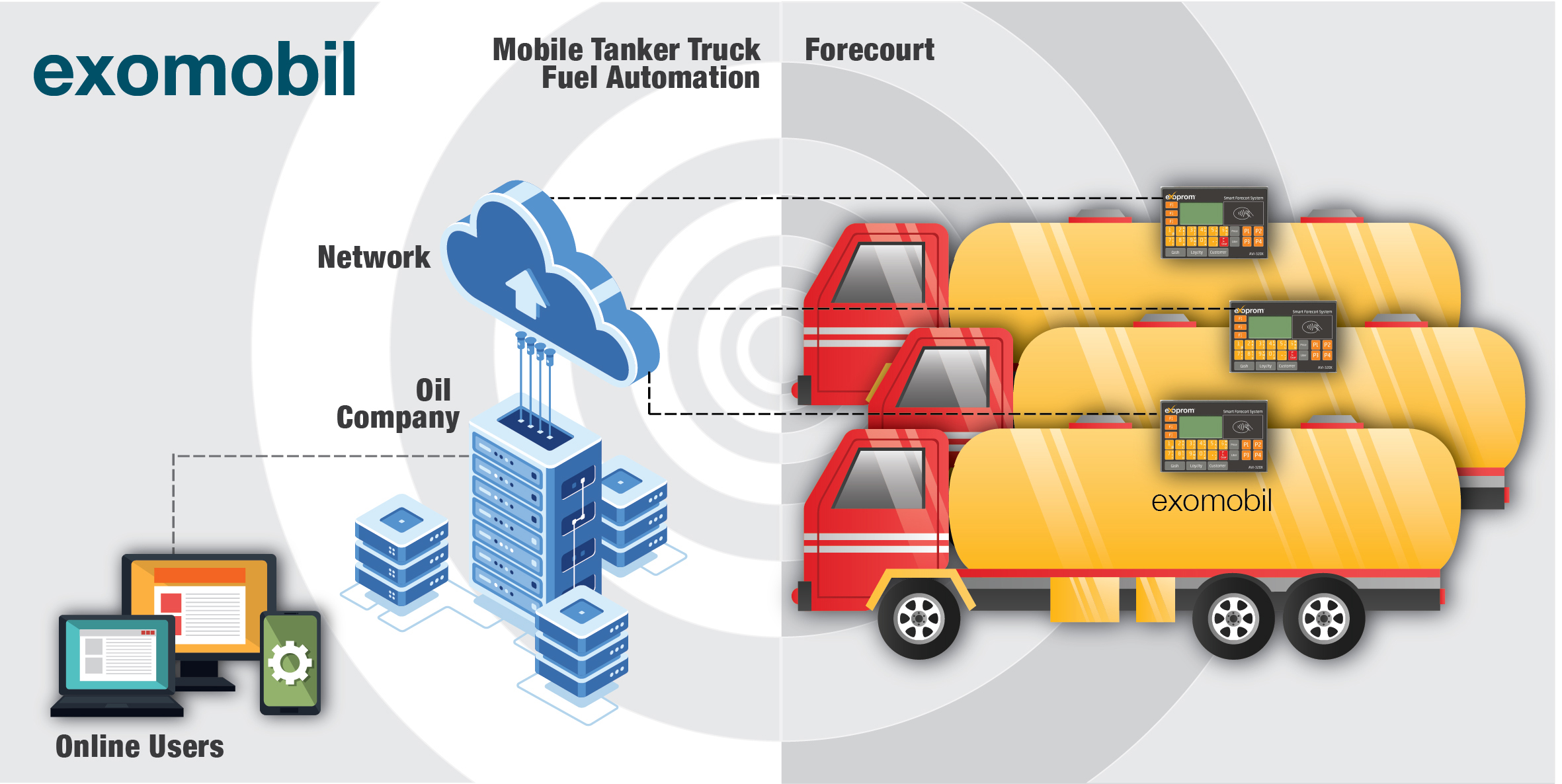

Exomobil – Mobile Solution for Mobile Tanker Control Uninterrupted Full Connection with the Tanker

Exomobile is a mobile tanker track controller specifically designed and developed for fuel tanker trucks. Exotank work in conjunction with Exosite and Exotank softwares and any dispensing of fuel is being controlled, consolidate and recorded on real-time at the field at real-time. It is designed for harsh conditions and extreme temperatures. It is stable, robust and also cushioning shock absorbers that dampen vibrations in harsh driving environments.

The control unit, monitors, stores and transfers each fueling activity per vehicle fueled on real time via Exofleet Solution. Beside if there is any problem at network (GSM communication) at the field authorization could be given by offline mode and all data kept by the system until network is available. Operation never stops. As soon as there is a network, Exotank sends all the data stored to main server. System successfully deployed in a variety of markets including road constructors, mines, airports and heavy construction sites . Exotank provides mobile fleet fuel savings of up to 30%. The fleet fueling system at ExoMobil is fully integrated with the Exosite and Exofleet RFID vehicle identification system for full control and maximum savings on fuel expenditures.

General Parameters

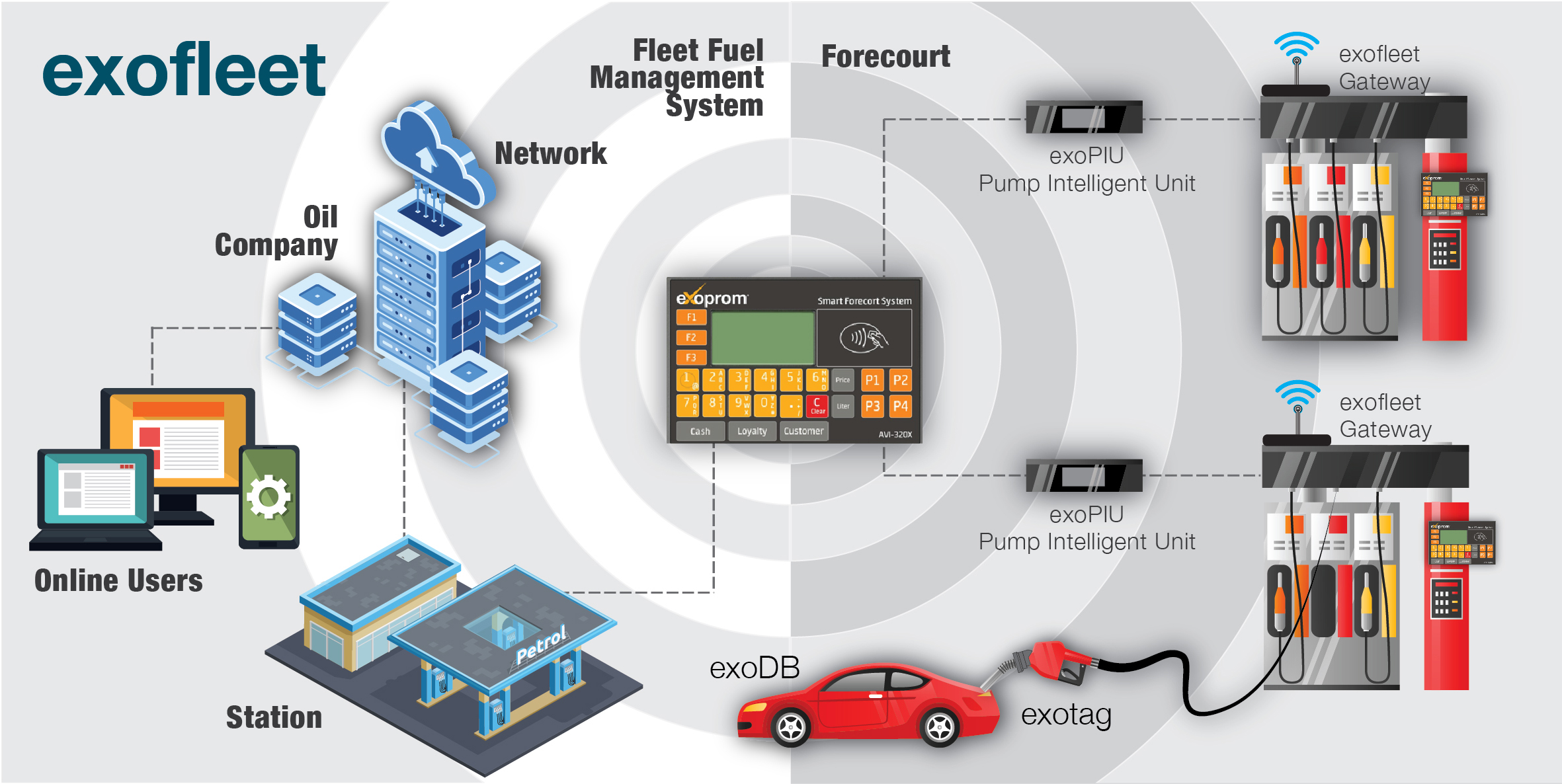

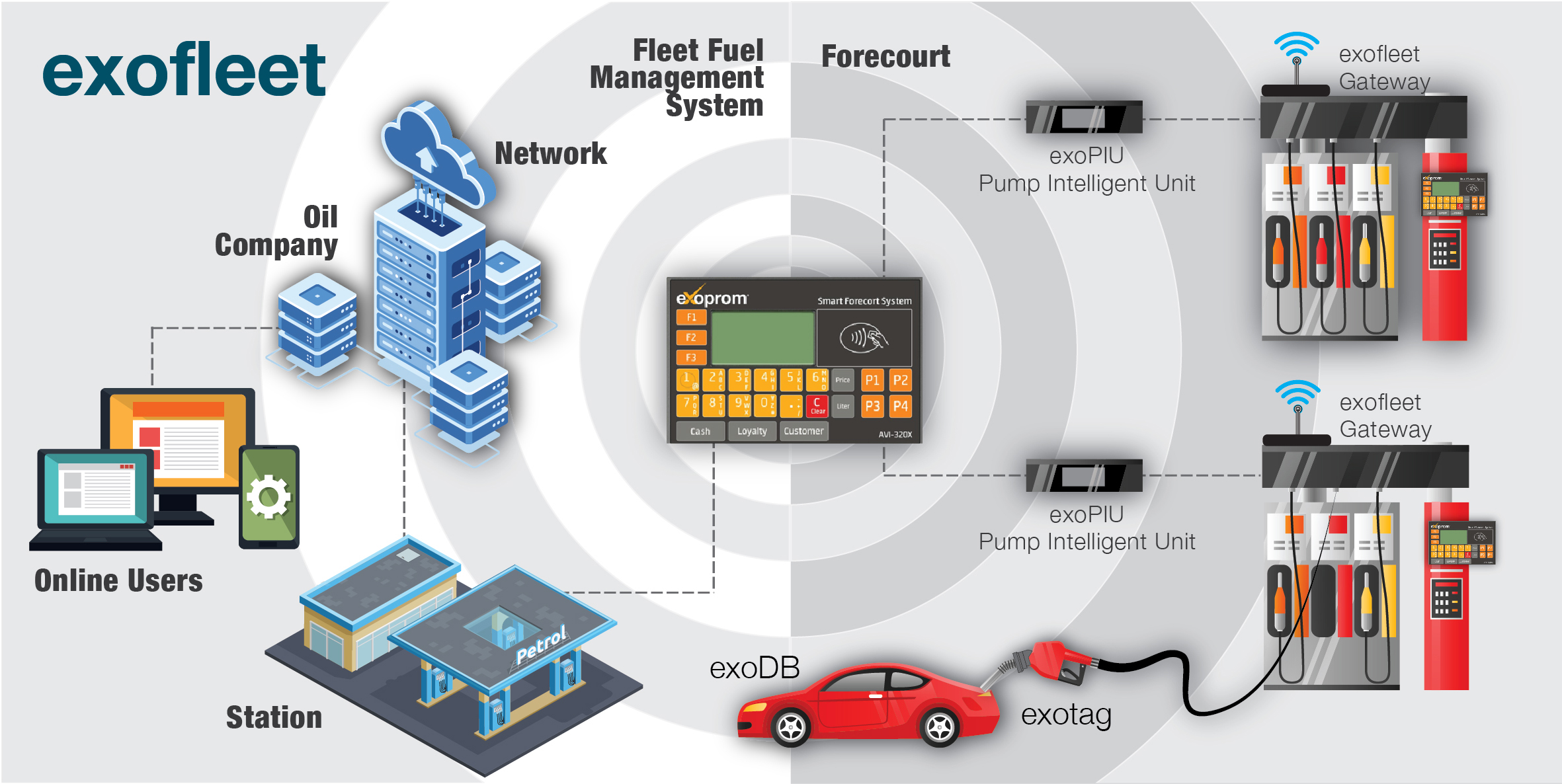

Exofleet (VRS)- Unrivaled Efficiency for Your Fleet

Exofleet (VRS)- Unrivaled Efficiency for Your Fleet

Exofleet is a modular and fully scalable end-to-end RFID vehicle identification automation solution for retail and commercial stations. Exofleets manages fleets fuelling per vehicle in all aspects together with pump attendant or driver authorization for multiple security options.

Exoprom’s Exofleet solution gives fleet managers a powerful set of fleet fuel management tools to efficiently run their fleets and control operations. Exofleet is a unique combination of Exoprom’s Exosite fuel management solutions. Advance fleet management needs smart, stable fuel control. Exoprom, focuses on fuel economy and helps fleet managers reduce fuel expenses and maximize their fleet efficiency together with increasing gross profitability.

General Parameters

With Exofleet, oil companies can provide value-added services to their fleet customers and increase their loyalty, while commercial fleets can add Exofleet’s powerful fuel economy management and get better consumption values per vehicle from the system.

Exofleet is a powerful integrated application that provides added value for fuel management of Exosite and Exomobil applications.

Exotrack - Your Eye on Your Fleet

Exoprom vehicle camera system consists of 2 systems that can be installed inside and outside the vehicle. In particular, the security camera system installed outside the vehicle is widely used in large construction equipment, excavation trucks, mobile fuel tankers, and waste and garbage collection vehicles.

Additionally, just like VIDEO ON DEMAND, the system has the ability to PUSH when requested.

Exotrack camera system PUSHes ON DEMAND. It adjusts the size and quality of the video to be sent according to your internet connection speed. Thus, it allows the image to be viewed even in field conditions where the internet connection is very weak. For example; if internet connection is weak, 144P 240P; 360P 480P as the internet connection gets faster; If there is a 4G connection, 720P 960P 1080P figures can be reached. We call this Adaptive Bitrate Streaming.

Exotire - Longer Tire Life

The Exoprom Tire measuring system Exotire has been specially developed to meet the challenge of monitoring commercial and private vehicle tyres.

Exotire sensors are attached to the rim or tire valve inside each tire and measure air pressure and temperature every 4 seconds. These values are sent via a radio frequency signal directly to the cabin display via a transceiver.

The display identifies the sensor, evaluates the data, then shows location, air pressure and temperature, and alerts if it detects any problems.

Exotire is also a system that can work integrated with the fuel automation system. When your vehicle comes to refuel, Exotire and Exopump communicate and warn you if there is any pressure change in your vehicle's tires. If desired, it even prevents the vehicle from receiving fuel and giving fuel before the tire pressures are brought to the desired level. In this way, drivers are ensured to pay utmost attention to tire pressure.

Exotire In Cab Display: The Integrated display and receiver unit monitor pressure and temperature information of each tire continuously. If the display shows a tire that is abnormal, the display will alert the driver of the condition before it becomes dangerous.

Tire Sensor: Mounted inside the tire on the center of the wheel, using cradle and steel. Monitor the tire’s pressure and temperature every 4 seconds and transmit data via RF to the integrated display at 30 second intervals when tires are normal or immediately when tires are abnormal.

ID Module: ID module is an international patented innovative technology used to identify tire’s position without any activation tool or complicated operation. Each ID module has an exclusive transmitter with the same ID code. The ID Module is mounted in the display and trailer. The ID box is to register the transmitter’s ID code into the display that will recognize each wheel position, as well as the baseline pressure for all tires.

Antenna: Installed under the chassis and near axles to collect the data of tires. An external antenna ensures signal reception reliability so that the integrated display always has up-to-date tire information.

Hand Held or Gate Reader: Hand Held or Gate Readers are used to read transmitter ID and tire information, register trailer, indicate battery status and store or transmit results to the data base.

Exon Fill&Go

Exoprom fuel technologies add value to your customers' time spent at the station with the fill-and-go application and provide reliable statistical reports on fuel purchases to oil companies.

How It Works

Benefits for Oil Companies