Exotank - Control Your Fuel, Adblue Storage Tanks With Wet Stock Management

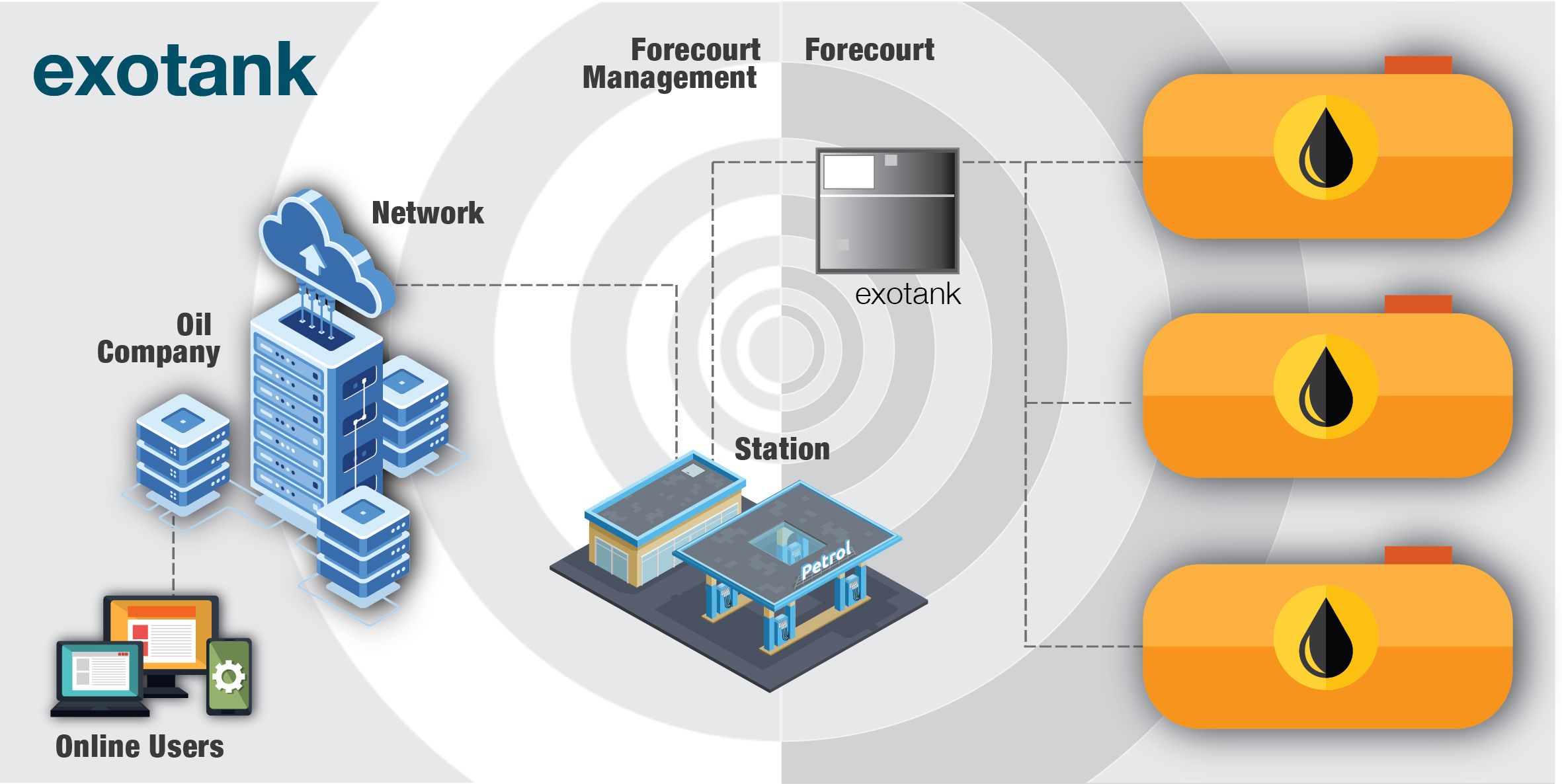

Exotank is a state of the art automated liquid inventory system designed to monitor, control and analysis real time liquid levels at storage tanks to reduce fuel loses, improve station network efficiency and gross margin. Exotank could be applied both as cabled or completely wireless depending on clients’ needs.

Fuel or adblue management begins with proper control of fuel inventory and smart purchasing policy and procedures. Exotank integrates with fuel station equipment and collects bulk data from all areas, tanks and pumps. Thanks to its smart algorithms, Exotank easily detects irregularities in station operations and stock levels at the beginning. It analyzes possible causes and allows you to make important decisions necessary to improve station performance. Exotank also tracks fuel stock history and looks for consistency in fuel input and output.

Exotank helps you consolidate the fuel you have on hand and record the correct amount of fuel per location by fuel type, allowing you to eliminate costly emergency deliveries. The Exotank is powered by Exosite software and fuel delivery is controlled and recorded in real time.

Exotank allows you to view full product usage and consolidate between products received, products shipped, and products left in storage tanks. All this will be done automatically via magnetostrictive independent level indicator sensors mounted on each storage tank.

General Parameters

Exotank enable to see full product use and consolidate between products received, products dispatched and products left in the storage tanks. All this will be done automatically via magnetostrictive standalone level gauge sensors mounted on each storage.

Delivery and Temperature Monitoring

Because Exotank continuously monitors inventory levels and temperature we are able to verify delivery amounts for short deliveries and identify offset fill leaks and hot product related losses issues.

Real Time Theft Alert

The real time nature of CFM means thefts can be identified quickly and accurately. The system will send out SMS or email alerts within couple of minutes of a theft occurring.

Meter Drift Analysis

Dispensers giving away fuel due to meter drift are probably the single biggest component of fuel loss. This service quickly highlights individual nozzles that can be economically cut back to strike without carrying out disruptive meter proving checks across the whole site.

Flow Rate Analysis and Dispenser Utilisation

The service also monitors the flow patterns of each dispenser throughout the transaction to identify any maintenance or performance issues. For example, slow flow due to blocked filters or significant changes in nozzle usage.

Water in Tanks

The presence of water in tanks can be advance warning of quality issues such as biological contamination and phase separation.

Wireless inlet RFID unit

Independent GPS odometer sender

Advanced vehicle telematics & diagnostics

Secure data collection unit

Fuel tank security unit

Driver & attendant ID

Radio frequency nozzle RFID unit

Site control unit